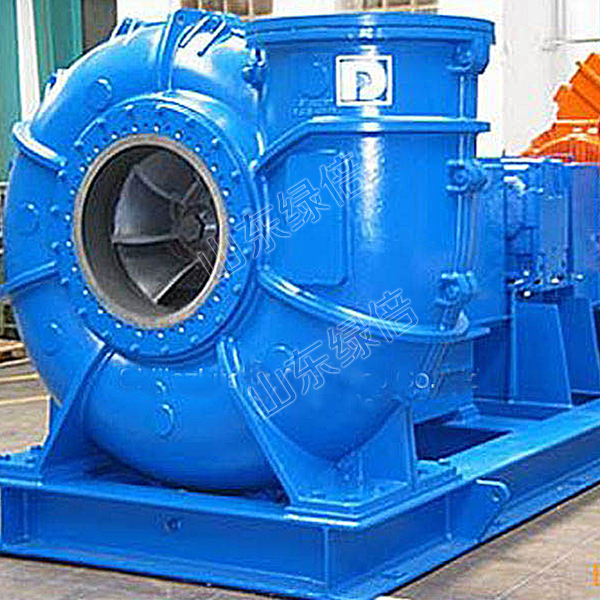

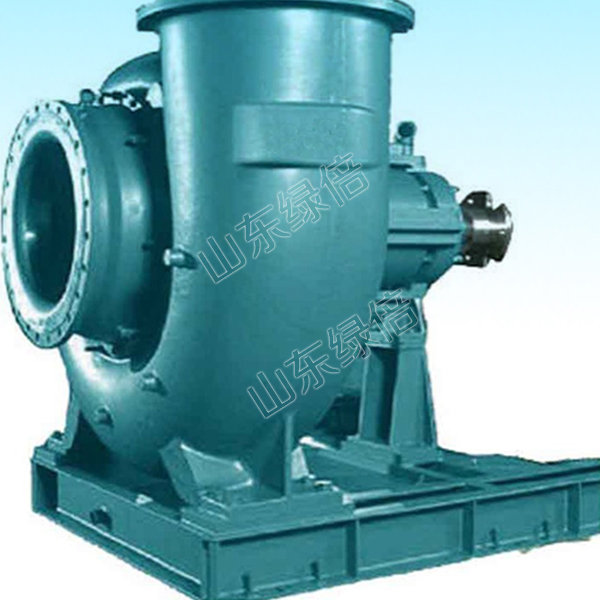

Maintenance And Overhaul Of Desulfurization Circulating Pump

First, the operation supervision

1. Whenever the desulfurization circulation pumpis running, it should be kept quiet and no vibration. Never let the pump run in the dry state. 2. Any spare pump that has been installed should be started once a week and disconnected immediately after startup to keep it operational. 3. During driving and running, you must pay attention to observe the meter reading, bearing heat, machine seal leakage and heat and pump vibration and noise are normal, if abnormal conditions are found, it should be dealt with in time. 4. The shut-off valve and other auxiliary pipes of the suction end cannot be closed during operation. The temperature of the bearing is not higher than the indoor temperature of 50 oC, and the high temperature of the zui must not exceed 90 oC. 5. The bearing oil level should be kept at the normal position, not too high or too low. When the temperature is too low, the lubricating oil should be replenished in time. Check the oil level (daily routine inspection)

Second, lubrication and lubricant replacement

Lubricate the pump with mineral oil to lubricate the rolling bearing. Unscrew the plug below the constant oil level oiler, drain the lubricating oil in the bearing housing of the desulfurization circulating pump, screw in the plug and add the bearing to the 46# turbine. Oil static oil lubrication. The temperature rise of the bearing does not exceed 50 ° C, and the maximum temperature does not exceed 90 ° C.

Third, disassembly

Pump maintenance and repair work must be performed by specially trained technicians and original spare parts must be used. Any operation on the motor must be carried out in accordance with the instructions and procedures of the relevant motor.

Note: Before disassembling the desulfurization circulating pump, make sure that the pump's power supply is not suddenly turned on, and close the shut-off valve and drain pipe of the suction end. The temperature of the pump's casing must be reduced to the room temperature. The outer casing of the pump must be free of applied pressure and the slurry must be completely drained.

Fourth, reinstall

The re-installation of the desulfurization circulation pump is carried out in accordance with strict engineering practice. Wipe all parts clean and check for wear. Damaged or worn parts should be replaced with original spare parts. Make sure the sealing surface is clean and the ferrule is properly installed. It is recommended to use a new seal (washer) whenever the pump is reinstalled. And make sure the new gasket is the same thickness as the old gasket. Prior to reinstallation, joints and bolted joints of single parts should be coated with graphite powder or other similar materials. Thoroughly tighten all screws and bolts during installation.